Production facilities

ILJEONG Industrial’s provides high-quality products

through state-of-the-art production facilities.

ILJEONG Industrial’s leads innovation in the textile industry with cutting-edge technology.

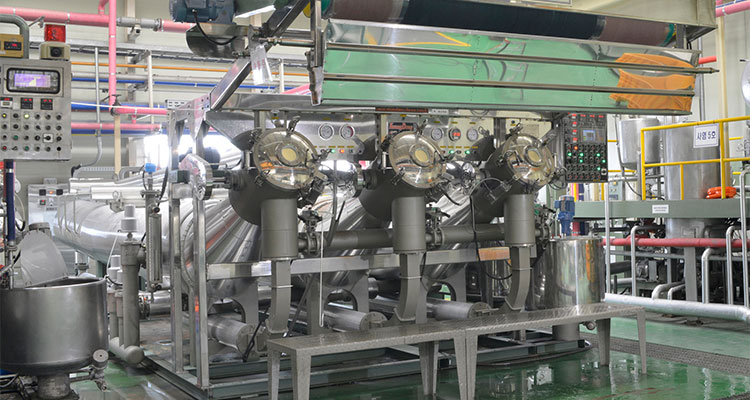

Dyeing Machine

Highly specialized machines that play a key role in large-scale textile dyeing processes, providing the flexibility to implement a variety of dyeing methods and conditions.

- Enhances driving stability by minimizing fabric tangling, friction, and wrinkling.

- Possesses 3 pilot dyeing machines and 5 production-scale machines.

- Equipped to dye fabrics in customer-specified colors.

- Excellent beating effect with special nozzles.

- 2Capable of producing 28,000 meters per day.

Tenter Machine

Used to fix the fabric width, evenly spread it, and perform heat treatment, drying, shrinkage prevention, and surface finishing.

- Equipped with 7 machines capable of water repellency, emulsion, coating, anti-mildew, flame retardant, and antibacterial treatments.

- Provides the advantage of various processing options to meet consumer demands.

- Smooths the fabric surface while maintaining uniform thickness and density.

- Processes at high temperatures to prevent shrinkage.

- Facilities for drying fabrics.

Dobby Moquette

Primarily used in public transportation seating, especially in buses, trains, and subways, this durable fabric is employed for drying, shrinkage prevention, and surface finishing, offering outstanding abrasion resistance and design.

- Forms a pile on the fabric surface to enhance various touch requirements.

- Equipped with 13 machines capable of producing pile fabrics.

- Maintains the original color and texture for a long time.

- Currently producing upholstery products for export.

- Available in a variety of colors and designs.

Jacquard Woven

Textile products created using special weaving techniques that can handle complex patterns, ideal for expressing luxurious and intricate designs.

- Provides a luxurious and sophisticated appearance thanks to complex patterns and textures.

- We have 5 machines and can promptly respond to customer requests for pattern designs.

- Possesses various equipment units, enabling both development and mass production.

- Equipped to weave various patterns and colors into woven fabrics.

- Used for interior decoration in automobiles.

Raising Machine

Equipment used to process the fabric surface to create a nap or pile, enhancing the fabric’s texture, insulation, and appearance.

- The process involves the fabric coming into contact with drums and being scraped by wires or brushes.

- We have the facilities to produce cut pile, loop pile, and suede pile fabrics.

- Possess expertise in pile processing to meet diverse consumer demands.

- Enhances the fabric’s volume and soft touch.

- Produces a range of soft automotive fabrics.

Shearing Machine

Equipment used to smooth and even out the surface of the fabric, primarily for removing unwanted fuzz, irregular pile, or fibers from the fabric surface.

- Used to enhance the quality of home textile products such as curtains, sofa covers, and bed sheets by employing a shearing machine.

- Contributes to improving the functionality and durability of the fabric, thereby enhancing the overall product quality.

- The shearing process is carried out to maintain a consistent loop or pile state formed by the pile.

- Plays a crucial role in fabrics with velvet, fleece, and other pile structures.

- Equipped with shearing facilities to increase the added value of the products.